This was actually a very tedious process, though I did get really good at soldering. I started off by bending all of the LEDs in the correct direction positive to negative and negative to positive.

I bought 4 1/16 inch blue strips of heat shrink, and 3 1/8 inch clear heat shrink to cover the resistors. I ended up having an entire strip of blue heat shrink left, and about half of my clear heat shrink. I measured and cut as many pieces of heat shrink as I needed for every LED.

After I cut the heat shrink, I put it on the LEDs. A few times I forgot to and had to un-solder everything, that sucked.

Then I put on the heat sinks, which was sometimes hard, because I still needed enough room to solder.

I simply melted some solder on the tip of the soldering gun and applied it to the wires. You have to make sure that you get the wires hot enough so that you don't have a cold solder.

Second I soldered the resistor.

I usually had to cut some of the LED wire off so that the resistor would fit between the two. I would use this spare wire to solder between 2 of the LEDs when they didn't reach each other.

I shrank all of the heat shrink with the tip of the soldering gun, plus, it looked cooler that way.

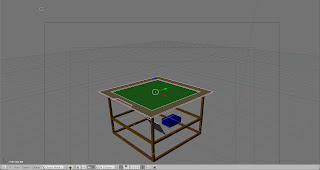

The final product looked something like this except with every single LED soldered.

Every single time I finished a set of 3, I tested it with a multimeter to see if the components still worked. When I was finished with every single rail, I soldered a wire along the positive sides, and a wire along the negative sides. I then tested that with a multimeter.

Through my regular camera, the final result looked something like this.

Through the IR camera, the results looked like this.

I am extremely pleased with the results I got. I wouldn't do anything different if I were to do it again. I might add more LEDs, but hey, I can still do that if things don't work out.

Works Sited:

Hewes, John. "Soldering Guide." Welcome to the Electronics Club. Web. 21 June 2010 <http://www.kpsec.freeuk.com/solder.htm>.